Without chiselling and demolition work

➦ As an innovative and modern company, we clean, inspect and renovate pipelines and wastewater systems using the latest, recognised technology at the highest level, coupled with a high and always individual level of consulting expertise.

Using the spray coating process, we renew broken pipes in the shortest possible time.

➦ This is possible because we utilise the latest findings from research and science and use them to refurbish the inside of pipes.

Your advantage as a property owner or resident: After just a few hours, the damaged pipe is repaired – and you are protected from further damage in the long term.

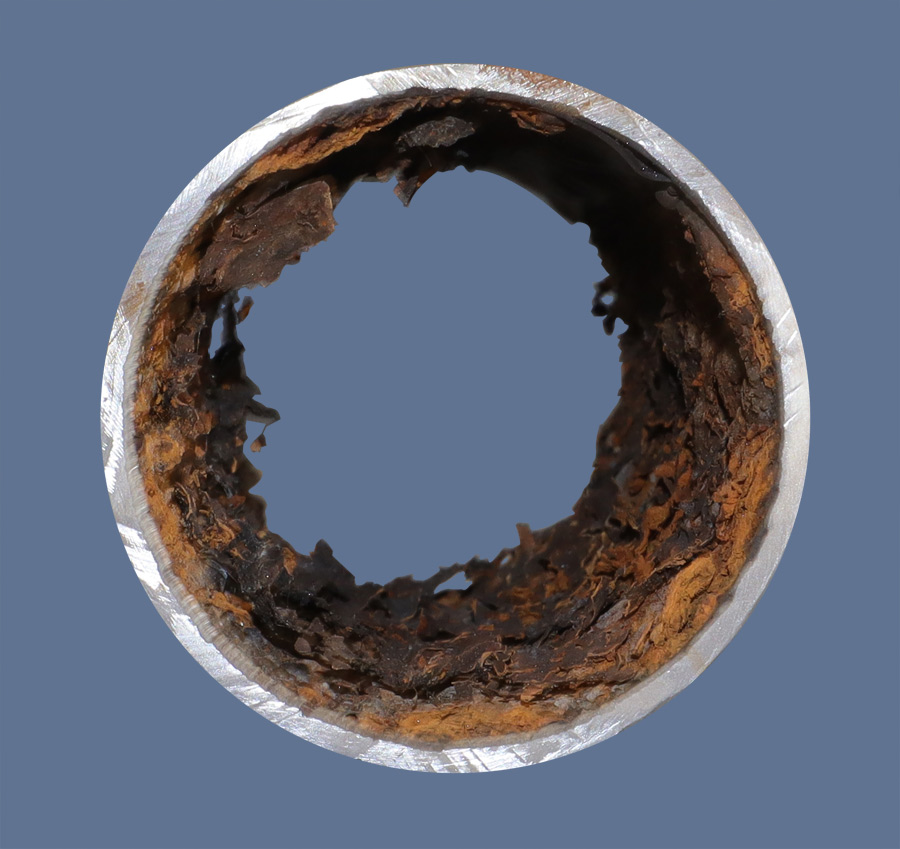

In-house modernisation of a cast iron pipe:

Before the modernisation

The pipe shows signs of damage and deposits.

After cleaning

The pipe is dry, free of dust and grease and free of deposits.

After the modernisation

The spraying process creates an intact, new pipe in the old pipe.

The polyester coating lasts for at least 50 years!

With the Proline spray coating process, we are able to completely refurbish complicated pipe runs from a diameter of 40 mm.

➦ Procedure

1. inspection

We carry out a systematic inspection of the entire pipework using a camera.

2. documentation

The weak and damaged areas are documented and marked on the corresponding pipe plan.

3. spraying process

The dried pipes are then sprayed from the inside with liquid polyester plastic. This is cured in layers and forms a new, intact pipe in the composite.

4. final documentation

Once our work has been completed, final documentation is drawn up. This is also used to check whether all damage has been repaired.

We look forward to your enquiry!

➦ Advantages

No disruption to your processes

You can remain in the building while the work is in progress. No moving of tenants, no covering of furniture or furnishings, no production stops – the work is organised in such a way that it can be carried out during ongoing operations.

Significant cost savings

of 30 to 50 % compared to open-plan construction

Simple handling

We don’t have to chisel open walls or tear up ceilings or floors.

Tested procedures

All the renovation methods we use meet the highest quality requirements, tested by the German Institute for Building Technology (DIBt) and other renowned institutions.

Strict quality control

The results of all refurbished pipes are subjected to strict quality control by a certified sewer rehabilitation consultant. You will receive comprehensive documentation.

Planning reliability

You receive reliable quotation calculations without hidden costs as the most economical complete solution, thanks to an individual evaluation of your project.